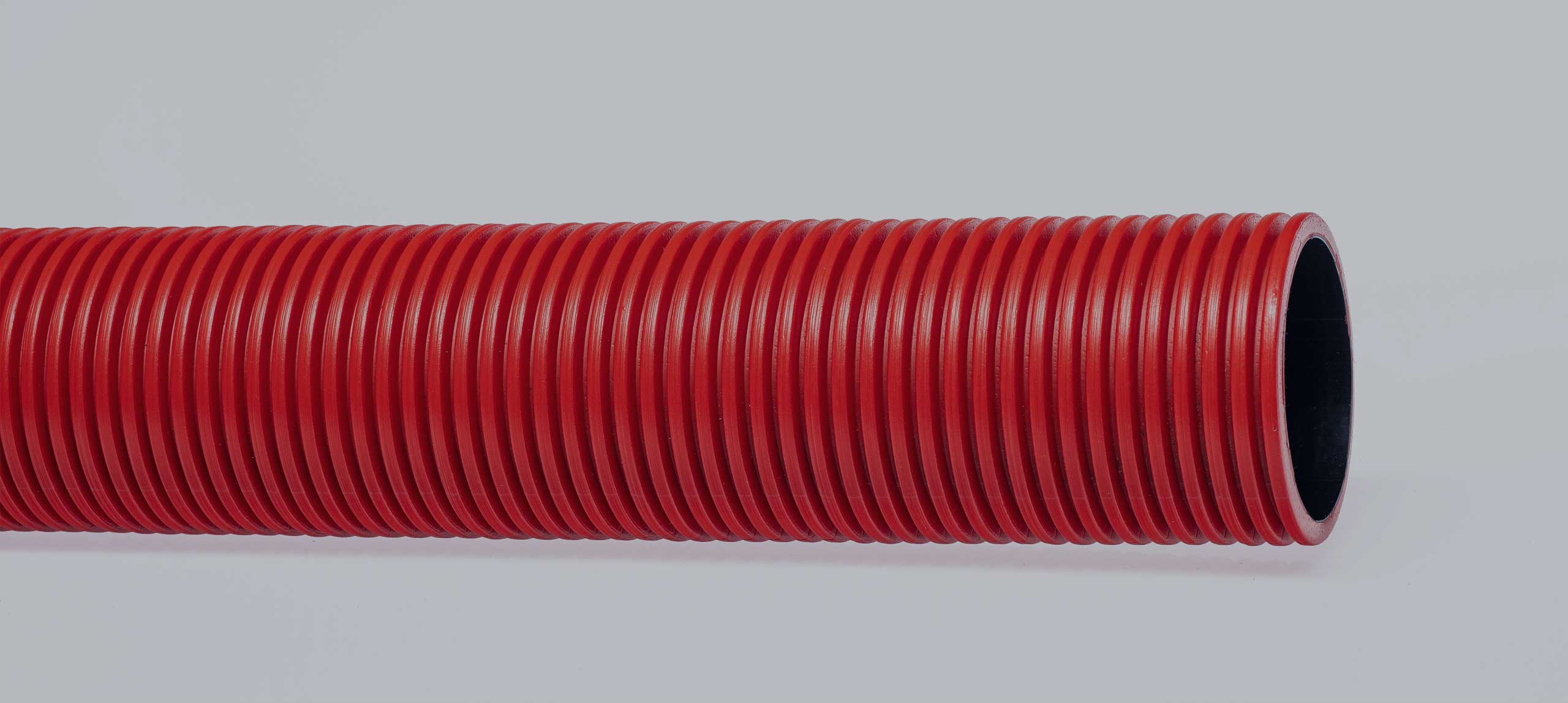

Properties of Stigmaflex® TK / EL pipes

The STIGMAFLEX® TK and STIGMAFLEX® EL piping systems have a number of good features, including:

- extremely low weight, which allows easier transport and easier installation

- excellent physical properties such as high circumferential stiffness and impact resistance, which ensures increased safety, durability and lower maintenance costs

- smooth inner surface that allows easy installation of cables

- exceptional corrosion resistance

- high insulation capacity and high voltage breakdown strength

- quick and easy installation of pipe systems

- lower joining costs, continuous laying and, due to flexibility, better adaptation to laying requirements

- possibility of installation even in extremely demanding temperature conditions (from – 40 ° C up to 80 ° C)

- environmental friendliness, as the pipes save more than 30% material and energy compared to conventional full-wall pipes, while allowing very simple recycling processes.

Standards:

SIST EN 61386

Quality Assurance

STIGMAFLEX® TK pipes are manufactured and tested in accordance with the applicable regulations for the use of telecommunications equipment and materials in the telecommunications network, as defined by Telekom Slovenije. The pipes also meet the requirements of STS-06/047.

STIGMAFLEX® EL pipes are manufactured in accordance with STS-06/048. In the manufacturing process, the applicable regulations and valid standards are observed.

STIGMAFLEX® requires continuous pipe inspection:

in the production process:

- dimensional control (outer diameter, inner diameter, inner wall thickness, wall thickness of the welded inner and outer layer)

- control of the appearance of the pipe (surface appearance, color, inscription on the pipe)

and regular testing:

- melt flow rate peak

- stiffness of the pipe (shape stability)

- impact resistance of the pipe

- tightness of pipe joints and joint pieces

Control and testing of both input materials and finished products is continuously performed in our own testing laboratory. We also perform constant control and improvement of the production process, all with the aim of adapting the level of quality to the ever-increasing requirements of technical regulations and the wishes of users.

In parallel with the internal testing, we obtained all certification approvals from competent institutions as evidenced by the issued test reports.