Due to their paraffin structure, high-density polyethylene (PE-HD) pipes are highly resistant to many chemicals, so polyethylene pipes are also often used to transport acids, alkalis and saline solutions. Chemical resistance is especially important for the drainage of feces and wastewater, as sulfuric acid is regularly present in these pipelines, which is a decisive factor in the durability of pipe systems. Corrosion due to volatile sulfides also occurs above the liquid level, which is especially critical for all cementitious binder materials, as this corrosion can erode up to six millimeters of cement wall in one year.

The table shows the approximate chemical resistance of polyethylene pipes to individual media or groups of media at certain temperatures. More detailed data for the chemical resistance of PE-HD to media are collected in the technical report ISO TR 10358 and DIN 8075 Beiblat 1. For the use of pipes in special cases, the manufacturer of the polyethylene raw material or the pipe manufacturer must be consulted in advance.

Chemical resistance of high density polyethylene pipes to individual media or groups of media at temperatures of 20 ° C and 60 ° C, where:

- (+) corresponds

- (0) partly corresponds

- (-) does not correspond to

- (*) consultation required

| Media | 20°C | 60°C |

|---|---|---|

| Acetone | + | + |

| Alcoholic beverages (up to 40%) | + | + |

| Ammonia (5x additional conc.) | + | * |

| Lime | + | + |

| Asphalt | + | 0 |

| Petrol | + | 0 |

| Bitumen | + | 0 |

| Citric acid | + | + |

| Detergents | + | + |

| Nitric acid (up to 10%) | + | 0 |

| Ethanol (96%) | + | + |

| Formaldehyde (up to 40%) | + | + |

| Glycerin (technically pure) | + | + |

| Kerosene | + | 0 |

| Acids (aromatic) | + | + |

| Glue | + | + |

| Chlorinated water | + | + |

| Fuel oil | + | 0 |

| Flaxseed oil (technically pure) | + | + |

| Lugi | + | * |

| Methanol | + | + |

| Mineral oils | + | 0 |

| Mineral water | + | + |

| Lactic acid | + | + |

| Milk | + | + |

| Sea water | + | + |

| Motorna olja | + | 0 |

| Engine oils | + | 0 |

| Acetic acid | + | + |

| Petroleum | + | + |

| Beer | + | + |

| Vegetable oils | + | * |

| Castor oils | + | + |

| Fruit (vegetable) juices | + | + |

| Hydrochloric acid | + | + |

| Liquid soap | + | + |

| Urine | + | + |

| Brake fluid | + | + |

| Animal oils | + | 0 |

| Mercury | + | + |

| Sulfuric acid (up to 10%) | + | + |

| Sulfuric acid (up to 30%) | + | + |

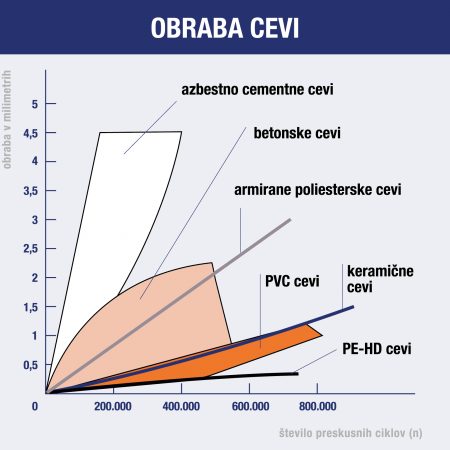

PE-HD pipes wear resistance

High density polyethylene (PE-HD) is extremely abrasion resistant and is one of the most resistant materials used to make pipes.

Extensive research on the wear of pipes made of various materials has been carried out at the University of Darmstadt on the basis of a recognized method by the Suddeutsches Kunststoff-Zentrum in Würzburg. The diagram shows the impressive properties that PE-HD pipes have in terms of wear resistance.